TrafFix Devices Big Sandy

![200 / 400 / 700 Lb. Barrels]() View Prices

View Prices200 / 400 / 700 Lb. Barrels

The smallest size Big Sandy barrel

Fill with 200 lbs, 400 lbs or 700 lbs of sand![1,400 Lb. Barrels]() View Prices

View Prices1,400 Lb. Barrels

The medium size Big Sandy barrel

Fill with 1,400 lbs![2,100 Lb. Barrels]() View Prices

View Prices2,100 Lb. Barrels

The largest size Big Sandy barrel

Fill with 2,100 lbs of sand

Traffix Big Sandy® Sand Barrels – TL-3 Impact Attenuator Systems

The Big Sandy® Impact Attenuator Sand Barrel System is a proven crash cushion solution used nationwide to protect motorists and workers at highway gore points, fixed objects, and barrier ends. Manufactured by TrafFix Devices, Big Sandy sand barrels are MASH TL-3 eligible and NCHRP-350 approved, making them suitable for high-speed roadway applications where predictable energy absorption is required.

Big Sandy barrels are engineered to break upon impact, reducing the likelihood of vehicle lift or vaulting while dissipating crash energy in a controlled, tested manner.

Why Big Sandy Sand Barrels Are Used in Work Zones

Big Sandy sand barrels are widely specified by DOTs and contractors because they combine regulatory acceptance, field-proven performance, and simple installation:

- MASH TL-3 eligible crash cushion system

- NCHRP-350 TL-3 approved

- Plastic construction designed to fracture on impact

- Compatible with standard 12-barrel TL-3 array designs

- Molded-in fill lines for easy visual weight verification

Because Big Sandy relies on gravity-based sand mass rather than anchors or mechanical components, it remains one of the most adaptable and forgiving impact attenuator systems available.

How Big Sandy Sand Barrels Work

Big Sandy barrels are installed in engineered arrays, not as standalone units. During a vehicle impact:

- Front barrels absorb initial kinetic energy

- Successive barrels progressively decelerate the vehicle

- The barrel shell fractures as designed to reduce lift

- Sand displacement dissipates remaining crash energy

This predictable energy management behavior allows Big Sandy systems to meet TL-3 crash testing requirements without anchoring to the roadway surface.

Available Barrel Sizes & Weight Options

Big Sandy uses three barrel types to create all required weights found in standard array plans.

Fixed-Weight Barrels

- 2,100 lb sand barrel

- 1,400 lb sand barrel

Combination (Multi-Weight) Barrel

A modular combination barrel can be configured in the field to:

- 200 lbs

- 400 lbs

- 700 lbs

The combination barrel uses a pedestal base and top half-barrel design, eliminating the need for shelves or cone inserts and helping reduce sand leakage.

All Big Sandy barrels feature reinforced lips for secure lid fit, UV-stabilized molded plastic construction, and molded-in fill lines for accurate weight confirmation.

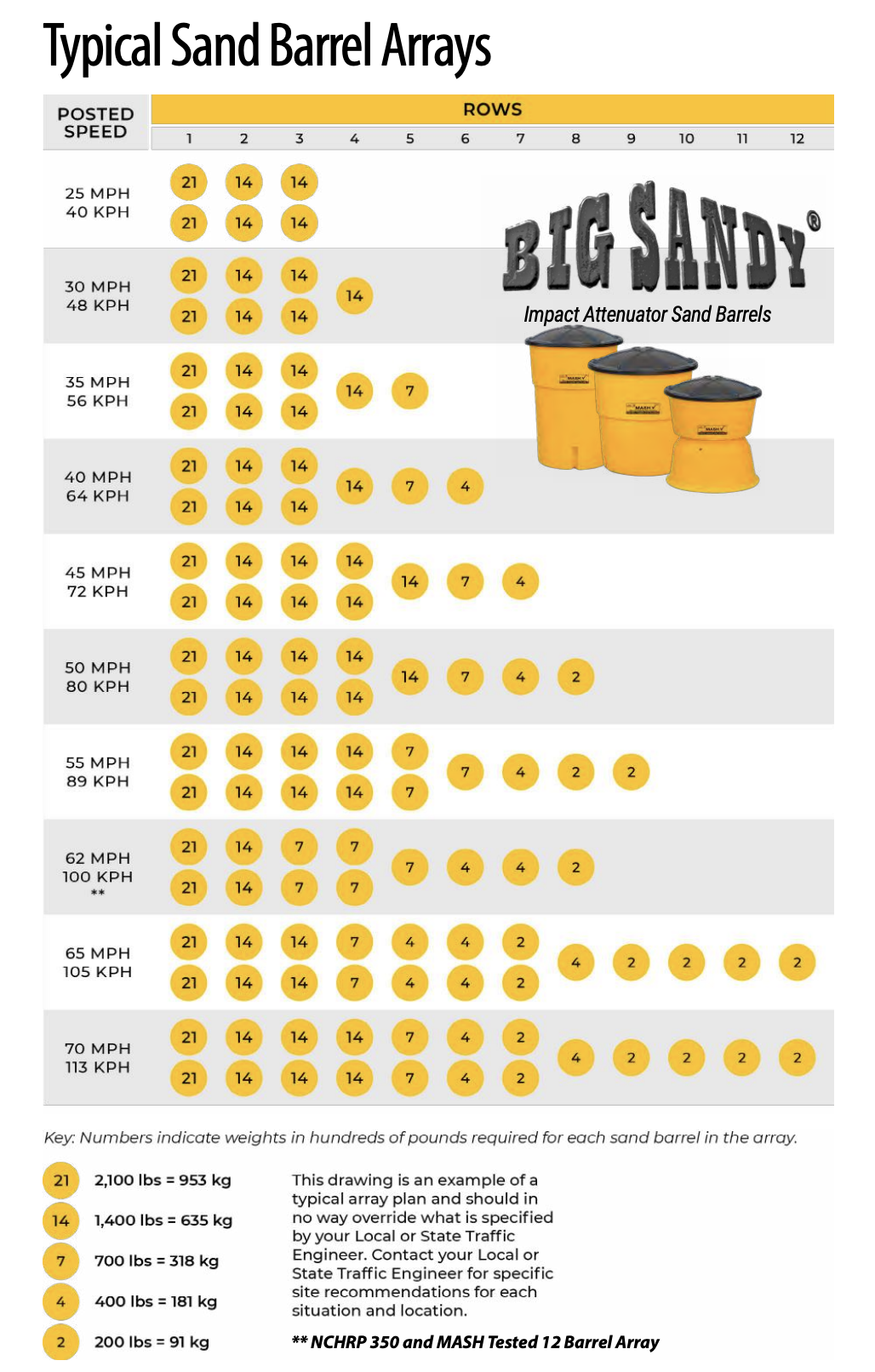

Typical Big Sandy Barrel Arrays

Big Sandy sand barrels are most commonly deployed in 12-barrel TL-3 arrays that have been tested and approved under both NCHRP-350 and MASH criteria. Barrel placement and weight progression vary based on roadway geometry and the object being shielded.

Important: Array configuration, barrel weights, and placement must follow applicable MUTCD guidance and state or agency-approved plans. Always verify requirements with the governing authority prior to installation.

Installation & Handling Advantages

Big Sandy systems are favored for their straightforward deployment and maintenance benefits:

- No anchoring or foundation work required

- Easy visual verification of correct fill height

- Optional lifting rings allow forklift handling

- Individual barrels can be replaced after impact

- Five-year prorated warranty against UV degradation

Common Applications

- Highway gore areas

- Bridge piers and fixed roadside objects

- Barrier ends and median openings

- Entrance and exit ramps

- Temporary and permanent work zones

Regulatory & Testing Summary

- MASH Eligible TL-3 Crash Cushion

- NCHRP-350 TL-3 Approved

- Production barrels identical to tested units

- Approved for mixing barrel types within arrays